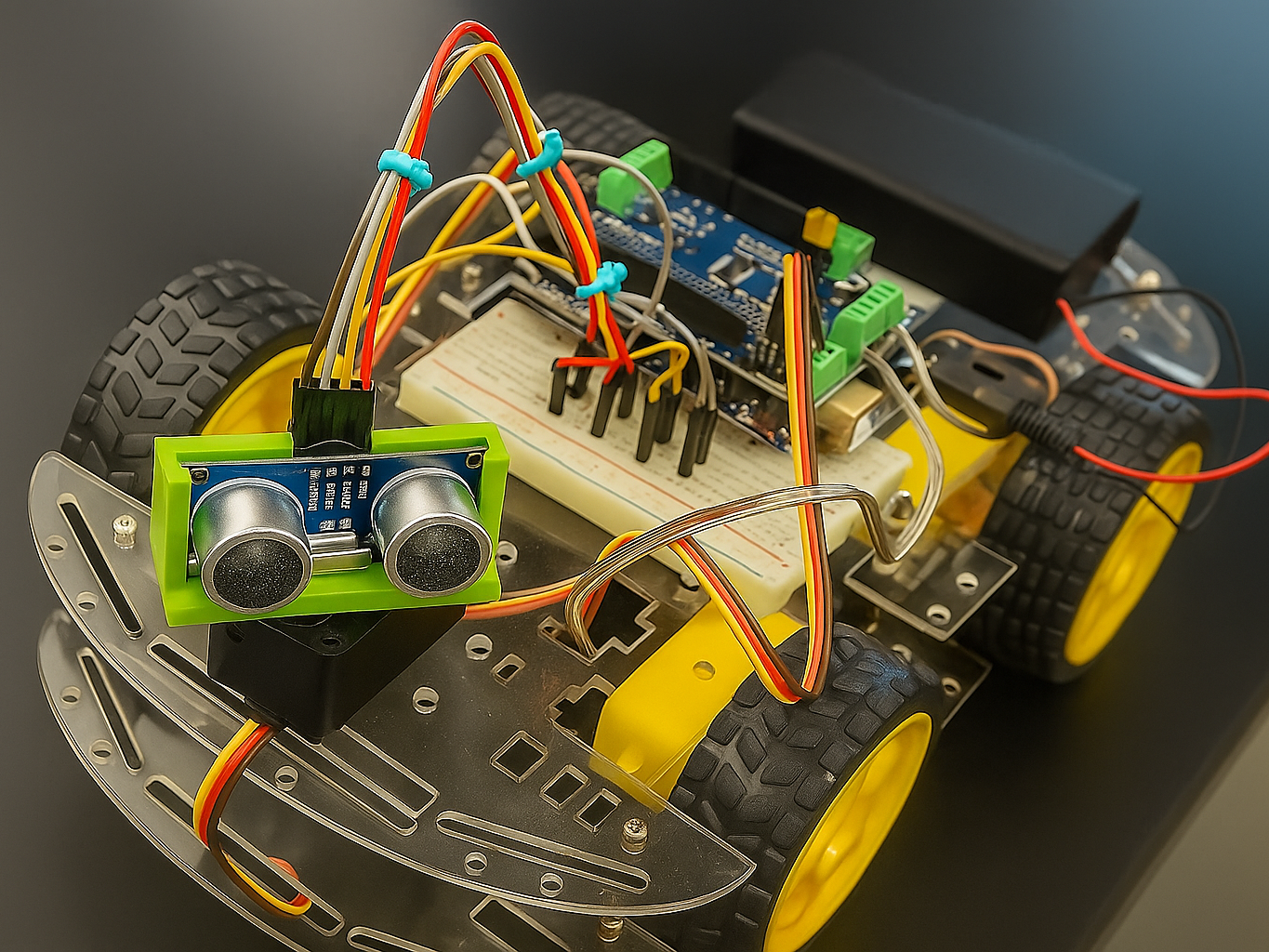

Soldering Projects were challenging but also a great learning experience. At first, I was nervous because I had never done it before, and I wasn’t sure how to connect the parts properly with the melted solder. As I practiced, I learned how to make sure the solder flowed smoothly and that the parts were securely attached without any mistakes. The hardest part was keeping my hand steady and controlling the heat, especially when working with tiny pieces. I also learned that patience is key because rushing could lead to problems that would take more time to fix. Overall, it was tough, but finishing the soldering felt really rewarding, and I got a better understanding of how important it is for the project to work.

Taking apart the dashboard to fix the PRND321 display was definitely a challenge. There were no schematics online, so I had to rely on YouTube for guidance, which turned out to be really helpful. However, while desoldering the MOSFET, I got a bit impatient and ended up ripping part of the PCB board that was wired. I had to improvise, as shown above to the right, but it ended up working. While it wasn’t my best work and the wire was stripped using alligator clips, it was a good challenge that taught me the importance of being patient. Rushing caused a major issue and ended up wasting more time as I had to figure out how to reroute the wires.

I decided to take on a challenge myself while designing a trophy that I wanted to light up. To make it happen, I started with a plain PCB board and a 120v to 9v converter, then created my own circuit design. I spent hours carefully putting everything together, and when I tested the circuit on a breadboard, it worked perfectly. However, when I tried to transfer the design to the PCB, it just wasn’t working. After a lot of troubleshooting and frustration, I discovered that I had been shorting the circuit the entire time. It turned out that there was an unintended connection somewhere in the design, causing the issue. Even though it was frustrating, it was a valuable learning experience. I learned the importance of checking and double-checking my connections and how crucial attention to detail is when working with PCBs. Despite the setback, it felt great to finally solve the problem and get everything working properly.