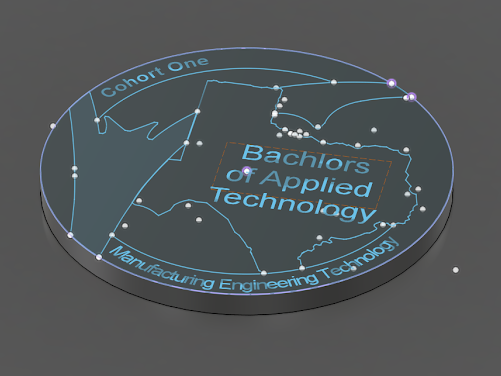

The following items were incorporated into course curriculums to enhance hands-on learning experiences. These components were thoughtfully designed by me and then 3D printed at the Impact Lab, ensuring that students have access to interactive, real-world applications that complement their theoretical knowledge.

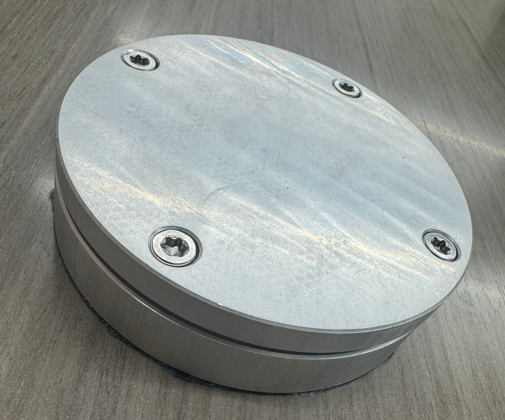

This object consists of a base and a removable top. Students are provided with the base and tasked with designing the top themselves. This exercise helps them understand the importance of tolerances in design. If the fit is too perfect, the top will be difficult to remove, while an excessive gap can affect the appearance and functionality. By taking precise measurements and applying their knowledge, students create their own custom top, gaining hands-on experience in balancing precision and practicality.

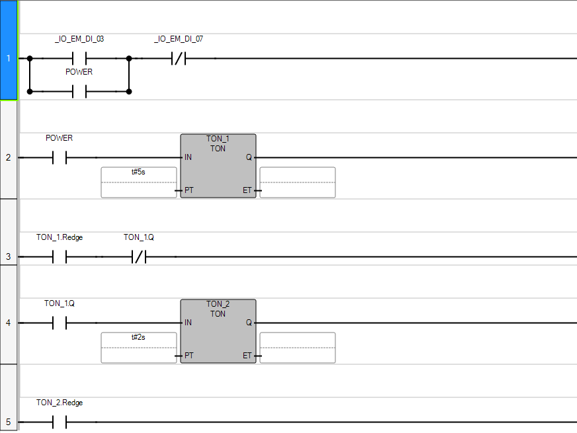

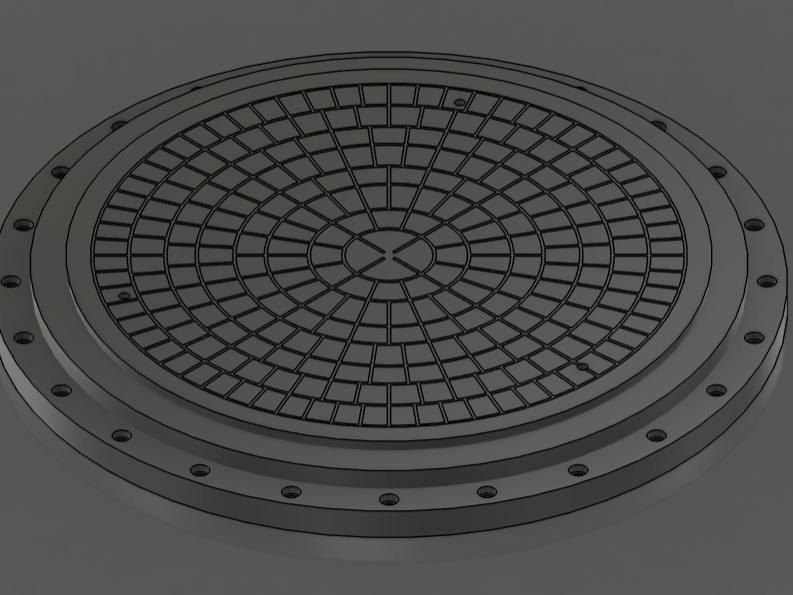

I designed this to give students hands-on experience with the star-pattern tightening technique, which is crucial for ensuring even pressure distribution on the Puck Plate. This technique prevents misalignment and ensures a proper seal, eliminating the risk of leaks that could lead to temperature inconsistencies, wafer defects, or process instability during semiconductor fabrication

This component was designed and manufactured from aluminum, while the puck I created was made of plastic. Due to its material properties, applying torque in foot-pounds directly to the plastic puck was impractical, as it would crack under excessive force. These miniature pucks serve as an ideal learning tool for students to understand how a torque tool functions and why it's essential to tighten in stages. If an SOP specifies a maximum torque of 50 ft/lbs, you don’t start at the maximum; instead, you progressively increase the torque in increments until reaching the designated value. This step-by-step approach is crucial because it ensures even distribution of force, prevents material damage, and improves overall assembly reliability.

Students are provided with two objects—one correctly manufactured and the other with defects. Their task is to analyze both and determine which one is faulty by referring to the blueprint above. To do this, they must carefully measure each component and verify whether the dimensions fall within the blueprint's specified tolerances. This exercise reinforces the importance of blueprints in manufacturing, as they serve as the standard reference for ensuring accuracy, consistency, and quality control. Without precise adherence to blueprint specifications, even minor deviations can lead to functional issues, assembly problems, or product failures.

I designed a template for students to match O-rings with their corresponding sizes. This hands-on tool is essential for teaching the importance of O-rings, including how to inspect them, avoid overstretching, and properly remove them.